Why Modern Risks Demand a More Adaptive Supply Chain Transformation Service

The rules of global business have changed forever. Predictable supply chains are a relic of the past. Today’s commercial environment is characterized by relentless disruption. Geopolitical instability is high. Climate events are more frequent. Consumer expectations shift instantly.

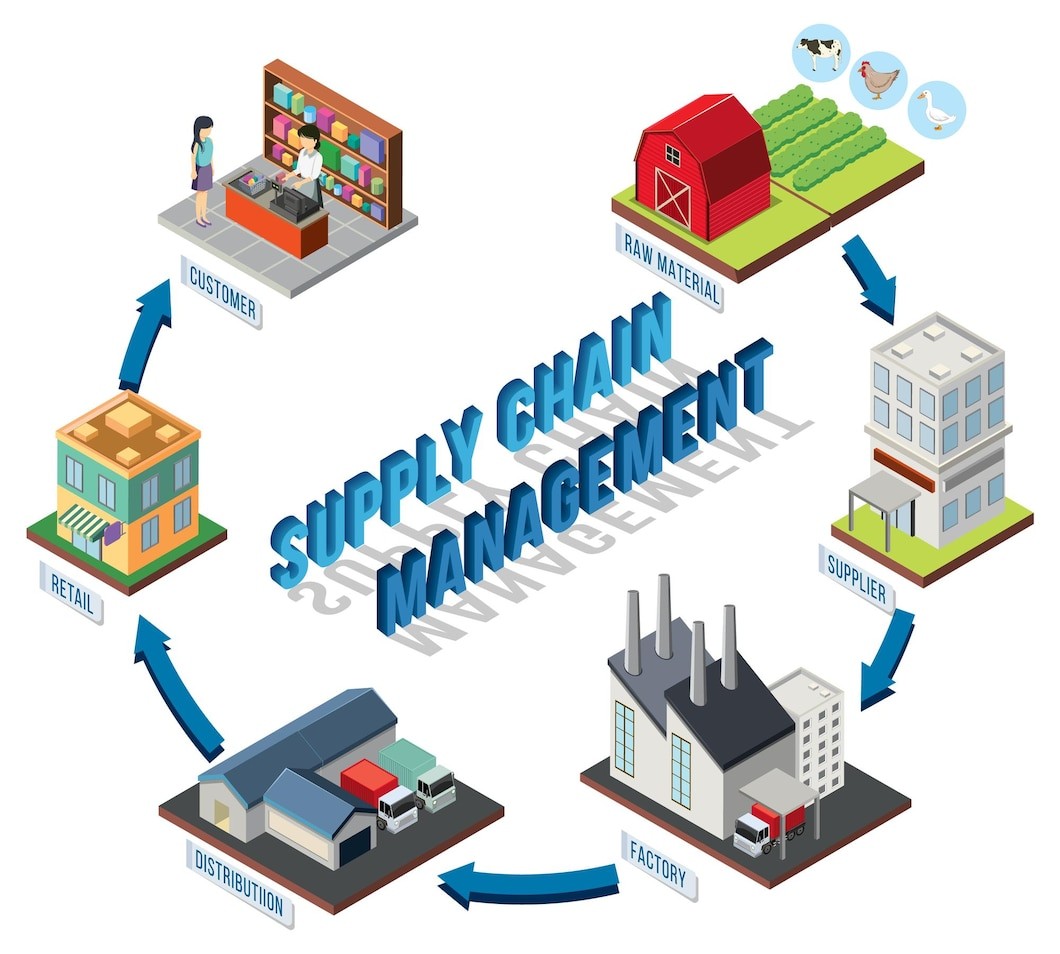

Legacy supply chain models cannot keep pace. They were built for stability and efficiency. They lack the necessary resilience and agility. Simply optimizing costs is no longer enough. Businesses now require a complete structural overhaul. They need a supply chain transformation service that builds adaptation into the very DNA of their operations. We see a clear, urgent demand for dynamic systems. These systems must anticipate risk. They must respond instantly to unexpected events. This shift from efficiency-only to resilience-first defines the modern mandate for transformation.

Moving Beyond Efficiency Traps

For decades, the core driver of supply chain design was efficiency. Businesses sought to reduce costs relentlessly. This led to strategies like single-sourcing and just-in-time (JIT) inventory models. These strategies minimized waste. They maximized margins during stable times.

However, they also created dangerous vulnerabilities. JIT systems lack buffers. A single delay or closure can halt an entire production line. Single-sourcing ties a company’s fate to one location or vendor. When the pandemic hit, or when political tensions escalated, these fragile structures broke.

The rupture revealed a fatal flaw: fragility. Modern risk requires a systemic countermeasure. Transformation must now be a strategic investment in robustness. It’s about designing optionality. It’s about building necessary redundancy. Businesses must accept that a 100% efficient chain is a 100% brittle chain. JEC Consulting Services helps clients shift this mindset. We focus on achieving optimal, sustainable performance, not just peak, fleeting efficiency. Our expertise in Design Consulting ensures systems are structurally sound from day one.

Geopolitical and Climate Volatility: The New Constants

The primary sources of supply chain instability are no longer just market forces. They are external, non-market risks. These risks are complex and often sudden.

Geopolitical Risk creates sudden trade barriers. Tariffs can appear overnight. Sanctions can instantly freeze key components. Companies cannot afford to rely entirely on regions prone to conflict or unpredictable policy shifts. This demands a diversified manufacturing and sourcing footprint.

Climate Risk poses a physical threat. Severe floods can wipe out port operations. Droughts can disrupt water-intensive manufacturing. This is not a future problem. It is happening now. A modern search for Supply Chain Transformation Service near me or anywhere else must factor climate resilience into site selection and logistics network design.

These new constants require a move toward regionalization. Long, lean global chains are being replaced by shorter, more manageable regional networks. This reduces transit time. It limits exposure to far-flung, unpredictable hazards. Adaptation means continuous risk modeling, not just reacting when a crisis hits.

Visual Proof and AI: The Power of Intelligence at the Edge

A critical part of modern precision involves visual proof. Video and data are collected throughout the logistics process. This often includes close-up video of goods. Data can come from barcode recording systems, warehouse management systems (WMS), and much more.

The intelligent video service links and correlates video with this collected data. The data may be interlinked with data in WMS, TMS, MES, or other systems. This integration makes it possible to search video material using order-IDs, specific events, or activities in the supply chain.

This capability is transformative for accountability. When a claim or deviation occurs, simply search the order-id or activity to get an instant view of related videos showing goods handled. This offers Visual Proof Of Shipping and dramatically aids Shipment Claims Reduction With video recording. Furthermore, we integrate AI to proactively guide your operations away from errors in real time.

Achieving Logistical Superpowers Through Integration

The combination of data, video, and AI in critical areas provides logistical superpowers. This integrated system allows companies to address their biggest pain points directly:

- Maintain Service Level Agreements across your supply chain and put an end to exhausting blame games. The immediate Order Fulfillment Recording provides immutable evidence.

- Cut costs, save money, and improve margins by eliminating manual checks and reducing loss.

- Stop errors in real time. Use retrospective analysis for fact-based continuous improvements. This is critical for processes like Conveyor Handling.

- Strengthen your brand and increase customer satisfaction by resolving disputes quickly and accurately.

- Take one more step towards sustainability by reducing returns and transportation inefficiencies caused by errors.

This precision technology fits companies with one warehouse, as well as companies with complex networks of DCs, warehouses, and hubs. It is perfect for warehouse logistics, manufacturing logistics, transport, last mile, and store logistics. We also offer a Free Executive summary for total transportation spend analysis for total Transportation Expenses to find immediate cost savings.

The Demand for Hyper-Personalization and Speed

Consumer expectations have changed fundamentally. They demand near-instant delivery. They expect personalized products. This puts immense pressure on the last mile of the supply chain.

Traditional fulfillment models, reliant on massive, centralized distribution centers, are too slow. Adaptive transformation focuses on distributed fulfillment. This means using smaller micro-fulfillment centers closer to population centers. It uses sophisticated inventory placement algorithms. The goal is to get the product to the consumer as quickly as possible, often within hours.

This speed requires a tight integration between e-commerce platforms and the physical supply network. Supply Chain Transformation Services in Georgia, for example, must account for both regional distribution challenges and consumer density. We help clients design these high-speed, localized fulfillment networks.

The Human Element of Agility

Technology and process design are only part of the transformation. The human element is often the most difficult to change. Legacy organizations often operate in silos. Procurement teams do not communicate effectively with manufacturing teams. Sales teams lack visibility into inventory levels. This lack of internal collaboration kills agility.

Adaptive transformation requires a cultural shift. It demands cross-functional collaboration. Teams must share information freely. They must have the authority to make rapid, distributed decisions. This means breaking down the traditional silos.

Transformation also involves upskilling the workforce. Employees need to be comfortable working with predictive analytics tools. They must be trained to manage multi-sourced supplier relationships. We work with our clients to design organizational structures and training programs that foster this necessary adaptability.

The Case for Adaptation Consulting

In a stable environment, a supply chain transformation was a one-time project. You planned for two years. You implemented three. You then managed it for a decade. That model is obsolete.

Modern risks are continuous. The response must also be continuous. We view transformation not as a project with an end date, but as a continuous capability. This requires supply chain management consulting in Georgia and elsewhere to shift its service model. It moves from one-off fixes to persistent, iterative improvement.

JEC Consulting Services provides this continuous adaptation framework. We implement systems that can be rapidly reconfigured. We install mechanisms for constant evaluation and optimization. This ensures that the client’s supply chain is a living, breathing network.

Conclusion

Modern risks—geopolitical tensions, climate volatility, and hyper-consumer demand—have irrevocably broken the old models of supply chain design. Efficiency remains important, but it must be secondary to systemic resilience. Businesses need an adaptive approach that integrates predictive data, leverages decentralized networks, and fosters a collaborative culture.

JEC Consulting Services specializes in this exact kind of deep, adaptive transformation. We guide organizations away from brittle legacy structures and toward the resilient, agile, and intelligent supply chain networks necessary for future success. Our expertise lies in diagnosing complex vulnerabilities and implementing comprehensive, sustainable solutions that include cutting-edge video, data, and AI correlation for unprecedented operational control. We work to ensure our clients’ operations can withstand the inevitable disruptions of the 21st century and protect both margin and market share.